Service

The R&D technical team is engaged in the research and development of strain test products and application technical services, and provides efficient and convenient test program customization services

Calibration and calibration services for torque sensors

- Categories:Technology service

- Time of issue:2022-02-11 11:38:36

- Views:0

Professional sample of torque

Torque is a special torque that causes an object to rotate, equal to the product of force and arm of force, in international units of N · m. The variation value of torque is important information for the operation status of mechanical power equipment.

The National Defense Science and Technology Industry High Torque Primary Measurement Station (hereinafter referred to as the Torque Station) is the earliest professional institution engaged in torque technology research in China. For a long time, it has served the metrological testing, measurement testing, and product services of weapons and equipment, with a history of over 40 years. Now, the torque station has provided comprehensive and lifelong torque value transmission services for equipment development, production, and testing in defense technology industry, military, and national economic construction, ensuring the accuracy of torque values in the Chinese People's Liberation Army, defense technology industry system, and national economic construction.

Business sector

Torque measurement

Calibration capability

| Serial number | Product / Category | Item/parameter | Calibration standards (protocols/specifications) |

| 1 | Torque standard machines | Torque | Torque standard machines(JJG769-2009) |

| 2 | Torque Toggle Checker | Torque | Torque Toggle Checker(JJG797-2013) |

| 3 | Torque speed measuring devices/torque meters | Torque | Torque speed measuring devices(JJG924-2010) |

| Rotational speed | Static torque measuring instruments(JJG995-2005) | ||

| 4 | Torque spanner | Torque | Torque spanner(JJG707-2014) |

| 5 | Standard torque meters | Torque | Standard torque meters(JJG557-2011) |

Testing capabilities

| Serial number | Product / Category | Item/parameter | Testing standards (protocols/specifications) |

| 1 | Torque spanners | Torque | General technical conditions for hand torque spanners(GB/T15729-2008) |

| 2 | Test stands for various types of naval main engines and power systems | Rotational speed | Ship's shaft power test methods(GJB2584-1997) |

| Torque | |||

| Power | |||

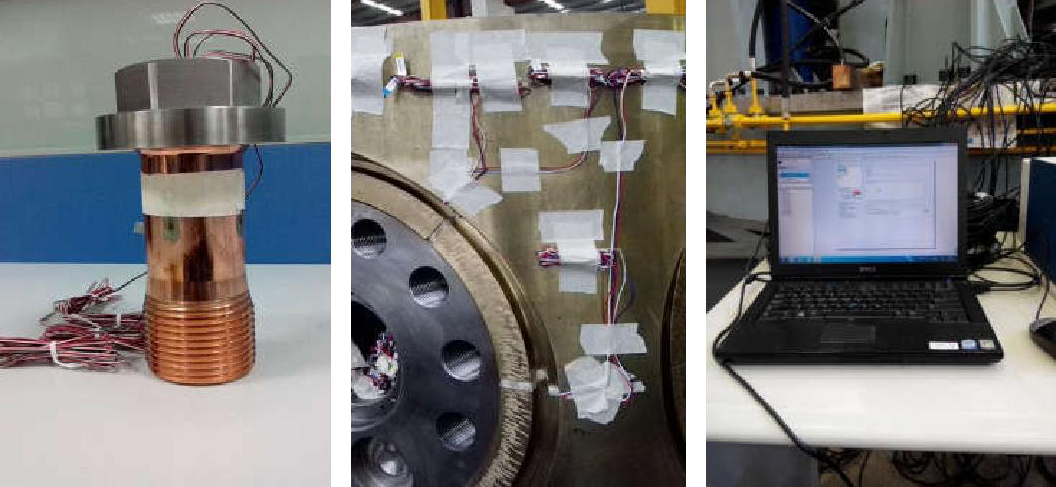

| 3 | Torque meters | Torque | Telemetry torque meters for ships(CB3410-1991) |

| Rotational speed | |||

| Dielectric strength | |||

| 4 | Torque speed sensors | Static calibration error | Torque speed sensors(JB/T6876-1993) |

| Sleeve error | |||

| Cornering error | |||

| Maximum torque | |||

| Insulation resistance |

Non-standard testing

Electric, pneumatic, and hydraulic bolt torque tightening tests; Various types of ship torque, power testing, and torsional vibration testing; Various types of torque testing machines; Exploration equipment, oil drilling, wind power, hydraulic motors, and various pump transmission torque and power testing; On site testing of stress and strain.

Training and technical consulting services

Basic knowledge training on measurement, training on torque measurement related standards and specifications, uncertainty assessment training, training on torque standard device standardization work, training on operation and maintenance of torque products, organizing torque measurement technology exchange activities or meetings, torque measurement technology consulting services, etc.

Characteristic measurement ability

1. High torque/ultra high torque (the only authorized unit for national torque measurement verification in the range range of 5kNm or above)

200kNm torque standard device

Measurement range: 2kNm~200kNm

Uncertainty: Urel=1 × 10-4 (k=2)

50kNm torque standard device

Measurement range: 50Nm~50kNm

Uncertainty: Urel=5 × 10-4 (k=3)

2. Small torque/small torque (can provide measurement services for the static and dynamic torque of key electromagnetic components such as torque sensors, angle sensors, magnetic bearings, locked rotor motors, gyroscopes, etc. in inertial navigation systems for weapons and equipment such as aviation, aerospace, and ships)

0.5mNm~10Nm air floating torque standard device

Measurement range: 0.5mNm~10Nm

Uncertainty: Urel=0.05%~0.01% (k=2)

Micro torque calibration device

Measurement range: (0.5~10) mNm

Resolution: 10-7Nm

Measurement uncertainty: U=0.1% FS (k=2)

3. Dynamic torque (can provide standard sinusoidal torque and negative step torque, calibrate the amplitude accuracy and time constant of torque sensors, and achieve accuracy evaluation of dynamic torque measurement. It is mainly used for power tuning of ship joint power systems and matching of ship class engines and propellers)

50Nm dynamic torque testing device

Uncertainty: U=5% (k=2)

Sinusoidal dynamic torque testing device

Measurement range: -5Nm~5Nm

Frequency: 1Hz~50Hz

Measurement uncertainty: U=5% (k=2)

Conventional metrology capability

Torque standard device

Measurement range: 0.282Nm~30kNm

● Uncertainty: Urel=3 × 10-4~1 × 10-3 (k=2

Measurement range: 2Nm~200Nm/20Nm~5kNm

Uncertainty: Urel=5 × 10-5 (k=2)

Standard torque meter/high-precision torque sensor and measuring instrument

Measurement range: 10mNm~50kNm/0.02Nm~50kNm

Uncertainty: U=0.1% (k=2)/U=0.03% (k=2

Torque standard machine

| High precision torque standard machine |

|

|

specifications:1Nm/10Nm/100Nm/200Nm/500Nm/1kNm/2kNm/5kNm/10kNm/20kNm |

| Level: better than 0.005% (k=2) |

| Note: Other specifications can be customized according to customers |

| Conventional torque standard device |

|

| specifications:10Nm/100Nm/200Nm/1kNm/2kNm/5kNm/10kNm/20kNm |

| Level:Level 0.03/Level 0.05/Level 0.1/Level 0.3 |

| Note: Other specifications can be customized according to customers |

Reference torque standard device

|

| specifications:10Nm/100Nm/200Nm/1kNm/2kNm/5kNm/10kNm/20kNm |

| Level: 0.03/0.05/0.1/0.3 |

| Note: Other specifications can be customized according to customers |

| Multifunctional torque calibration device |

|

| Specification: 20kNm/50kNm/80kNm |

| Level: 0.3 |

| Purpose: Used for calibrating hydraulic wrenches, pneumatic wrenches, and multipliers |

| Note: Other specifications can be customized according to customers |

Torque wrench calibrator

|

| Specification: 200Nm/1kNm/3kNm/5kNm |

| Level: 0.3 |

| Data collection method: automatic/manual |

| Note: Other specifications can be customized according to customers |

Telemetry power meter

|

|

| Military telemetry power meter | Civil shaft power meter |

| Maximum allowable error: ± 0.5% FS | |

| Speed: (300-500) r/min | |

| Note: Other specifications can be customized according to customers | |

Solution

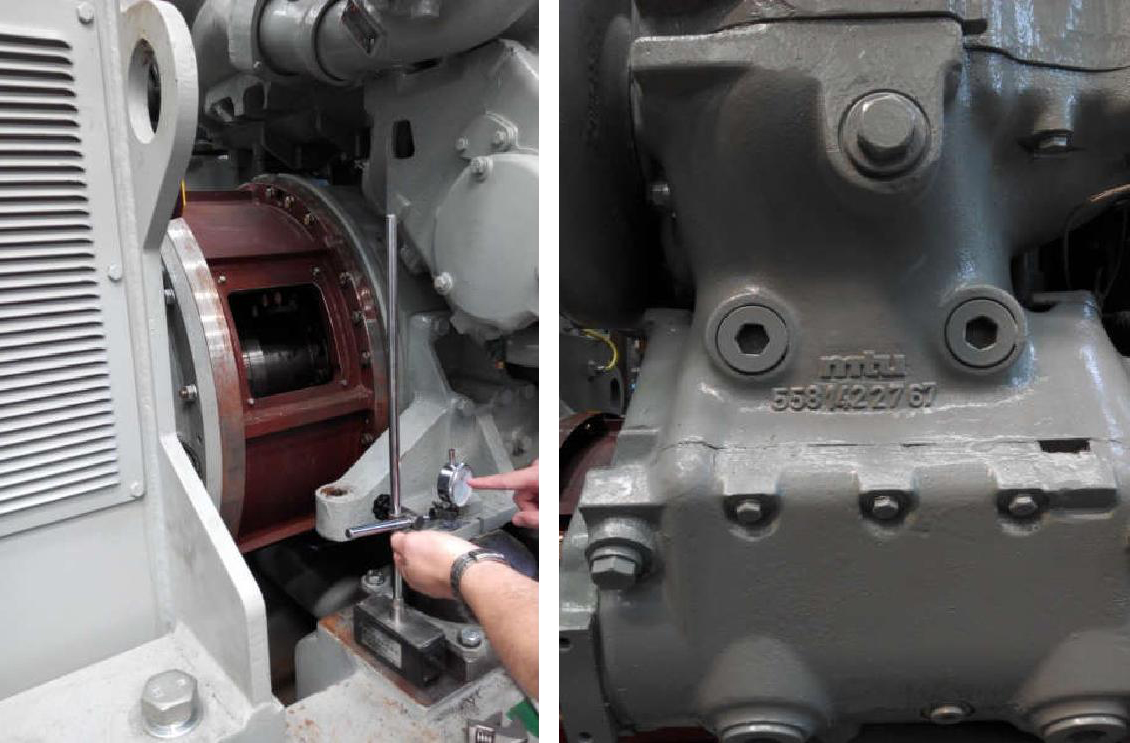

Shaft power test case I:

Shaft power test case II:

Testing of starting speed, torque, and power of side thrusters

Structural stress test case I:

Structural stress test case II:

Test case of shafting Torsional vibration:

Case 1 of non-standard customized devices:

The 2-ton balance is a national benchmark of the Chinese Academy of Metrology, used for the traceability of weights. The device adopts a structure of knife edge support and weight loading. The entire device has a delicate appearance, high degree of automation, high measurement accuracy, and is internationally leading.

Case 2 of non-standard customized devices:

User Unit

Follow us for more information

-

【 Official WeChat 】

【 Official WeChat 】

-

【 Mobile Website 】

【 Mobile Website 】

Tel: 400-8067-299

- Service Hotline 400-8067-299

- Service Mailbox right@ritcl.com

- Pre-sales Advice 189 2107 0677

Follow Right

Follow Right